The Ultimate Solution for Precision Printing

What is Pad Printing?

Pad printing, also known as tampo printing, is an advanced method of transferring ink from a 2D image onto a 3D object. This versatile printing technique is widely used in industries ranging from medical devices to automotive parts, promotional goods, and electronics.

How Does Pad Printing Work?

Pad printing involves the use of a silicone pad to transfer ink from an engraved cliché plate to a substrate. The pad picks up ink from the plate and then compresses onto the surface of the object, ensuring that even curved or irregular shapes can be printed with clarity and precision.

Why Choose Pad Printing?

Pad printing is an essential technique for industries that require high precision and fine detail, particularly on challenging surfaces like cylindrical or irregular shapes. With the capability to print on surfaces that other methods cannot handle, pad printing stands out for its versatility and effectiveness. It is commonly used for:

- Printing logos, icons, and text on products

- Decorating small objects such as pens, bottle caple toys, and medical instruments

- Marking complex surfaces like electronic components

The Pad

The pad in pad printing is made from silicone, which is flexible and elastic, allowing it to adapt to various surface shapes. It transfers the ink from the cliché plate to the object. The elasticity of the pad ensures that the image is transferred without distortion, making it ideal for printing on uneven surfaces.

The pad's shape, hardness, and composition vary depending on the application and the type of object being printed. Whether you're working with flat, concave, or convex surfaces, the silicone pad can adjust to ensure a perfect print every time.

The Cliché Plate

A cliché plate is a metal or ceramic plate that holds the image or design to be printed. The image is etched or engraved onto the surface of the plate, where the ink is applied. In pad printing, the cliché is the essential component that defines the quality of the print. At Epic Pad Printing, we use only high-quality materials to ensure that our clichés provide precise and sharp prints, even after repeated use.

- Types of Cliché Plates: There are two main types – steel and ceramic.

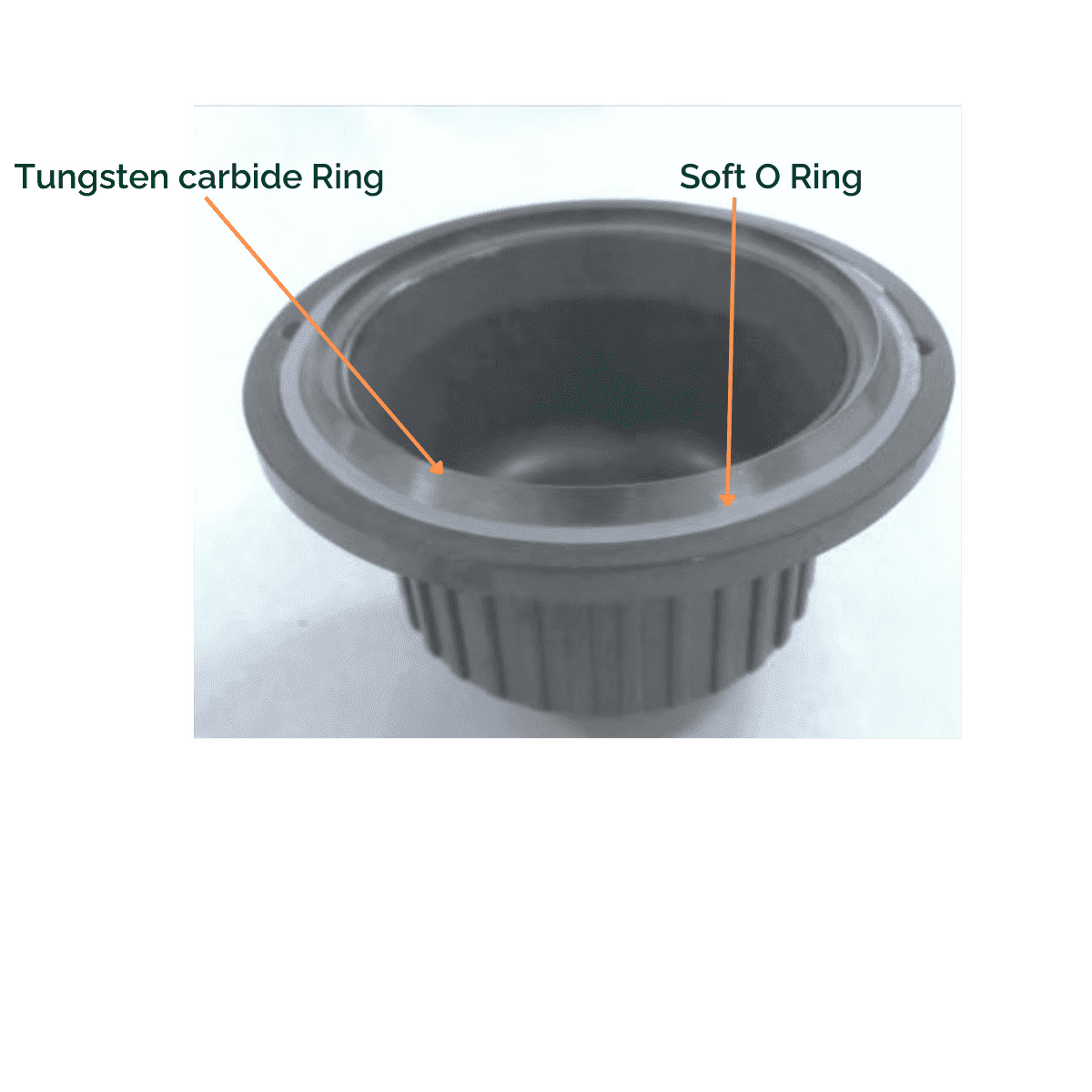

Ink Cup

The ink cup is another essential component in the pad printing process. It is designed to hold the ink and apply it onto the cliché plate, allowing the pad to pick up the ink. The ink cup also helps maintain a controlled amount of ink during the printing process.

At Epic Pad Printing, we Non – magnetic inkcup. The Non – magnetic inkcup system reduces ink evaporation, extends the life of the ink, and minimizes fumes, making it an environmentally friendly option.

Pad Printing Ink

The type of pad printing ink used is critical to achieving a high-quality print. Pad printing inks are specially formulated to adhere to a wide range of substrates, including plastic, metal, glass, and ceramic. Our inks are designed to provide vibrant colors and excellent durability, ensuring that your printed designs stand the test of time.

Our range of Epic Pad Printing Machines is designed for precision, durability, and ease of use. Whether you need a machine for small-scale operations or industrial-level printing, we offer a variety of models tailored to different production needs. Each machine is built with the latest technology and is designed for efficient, high-quality output.

High Precision: Our machines provide excellent accuracy, making them perfect for detailed designs and logos.

Versatility: Whether you're printing on flat, cylindrical, or irregular surfaces, our machines can handle a wide range of materials and shapes.

Durability: Built to last, our pad printing machines are made from top-quality materials, ensuring they can withstand rigorous use in any production environment.

User-Friendly Operation: We design our machines with simplicity in mind, ensuring they are easy to operate, even for those new to pad printing.

Customizable: Our machines can be tailored to suit your unique printing needs, whether you're working with specific substrates or designs.

At Epic Pad Printing, we provide a full suite of services designed to help you get the most out of your pad printing systems. From initial consultation to installation and ongoing support, we are committed to ensuring your success.

- Consultation and Design : We understand that every business is unique, and that's why we offer custom consultation services to help you choose the best equipment and materials for your specific needs. Our team of experts will guide you through the process, ensuring that you have the right combination of machine, ink, and accessories for your project.

- Installation and Training : Once you've selected the perfect pad printing system, our team will provide installation and setup services to ensure everything is functioning correctly. We also offer comprehensive training sessions to get your team up to speed on operating the equipment and troubleshooting any issues that may arise.

- Maintenance and Support : To keep your pad printing system running smoothly, we offer routine maintenance and repair services. Our expert technicians are always on hand to perform regular checkups and provide quick repairs to minimize downtime and keep your production line moving.

- Our Approach to Pad Printing Solutions : At Epic Pad Printing, our approach is centered on innovation, quality, and customer satisfaction. We believe that success comes from understanding your unique challenges and delivering solutions that exceed your expectations.

- Customer-Centric Solutions : Our team works closely with you to understand your printing requirements and to provide the most effective solutions. We tailor our machines and services to meet your specific needs, ensuring that you get the best possible results.

- Focus on Quality : We use only the highest quality materials and components in our pad printing machines, ensuring durability and reliability. Our rigorous testing and quality control processes guarantee that every machine we deliver performs at the highest standard.

- Continuous Innovation : In a rapidly evolving industry, we are committed to staying at the forefront of technology. Our research and development team constantly works on improving our machines and inks to ensure that we offer the latest advancements in pad printing technology.

FAQ's

Ques 1 : What types of substrates can be printed with pad printing?

Answer: Pad printing can be used on a wide variety of materials, including plastic, metal, glass, ceramics, silicone, and rubber. It is especially useful for printing on irregularly shaped objects and surfaces that are difficult to print on using other methods.

Ques 2 : How do I choose the right ink for my pad printing project?

Answer : Choosing the right ink depends on the substrate you're printing on. For hard surfaces like metal and glass, we recommend using two-component inks with hardeners. For softer plastics or silicone materials, single-component inks are typically sufficient.

Ques 3 : How often should I maintain my pad printing machine?

Answer: Regular maintenance is key to keeping your pad printing machine in optimal condition. We recommend performing basic maintenance, such as cleaning and lubrication, after every use. For more intensive maintenance tasks, it is best to follow the manufacturer’s guidelines or contact a professional technician.

Ques 4 : Can pad printing be used for high-volume production?

Answer: Yes, pad printing is highly efficient and can be scaled for high-volume production. With the right equipment, you can automate the process and produce thousands of printed items in a relatively short amount of time.