Tampon printing for pharmaceutical, healthcare, nutraceutical, Cosmeceutical and medical sectors

Pad printing is a versatile printing method widely used in the medical industry for printing on various medical devices.

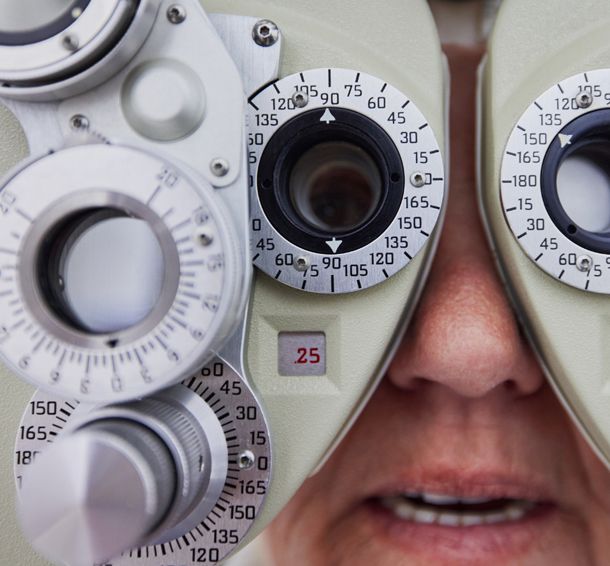

Some of the medical devices that often require pad printing include:

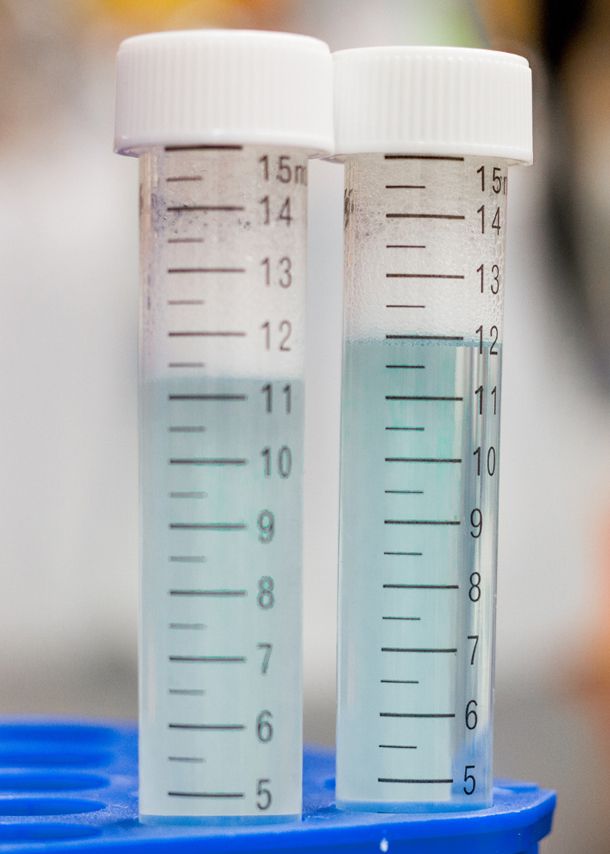

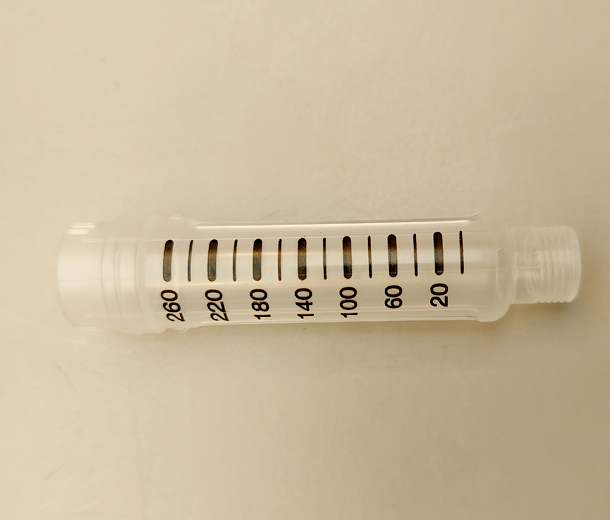

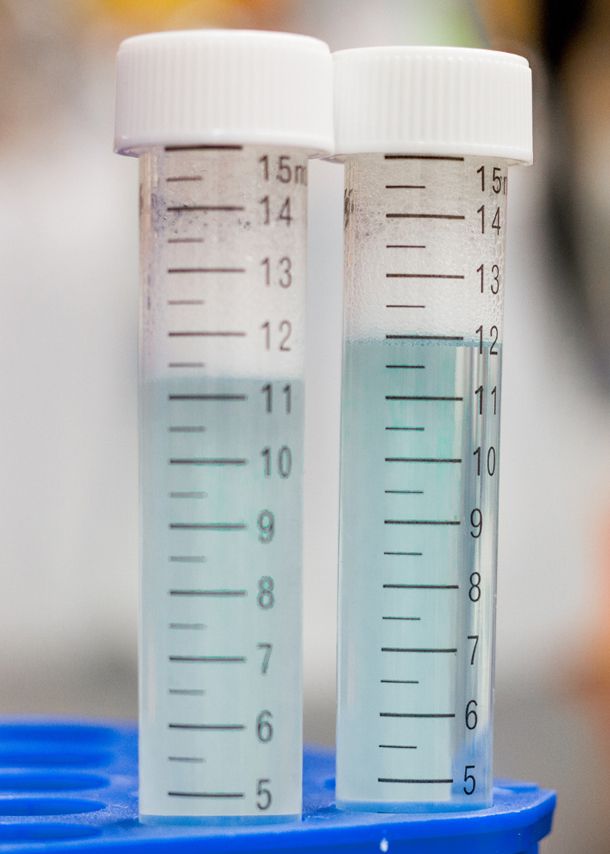

Syringes: Pad printing is commonly used to print measurement markings, branding, or other information on syringes, ensuring clear and durable markings on syringes. White writable patches are also done on lab graduated centrifuge tube with pad printing, which makes the centrifuge conical tubes, reusable and writable.

Medical Instruments: Pad printing is employed to mark medical instruments such as forceps, surgical scissors, clamps, and retractors. It allows for the printing of logos, identification numbers, or other relevant information for easy identification and traceability.

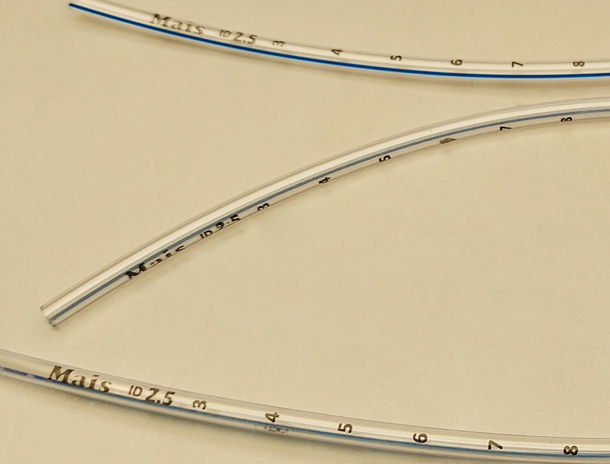

Catheters and Tubing: Pad printing is used to print important information, like size indicators, on catheters and tubing to ensure accurate usage and patient safety.

IV Sets: Pad printing is utilized to mark IV sets with important information, including flow rates, instructions, or branding.

Implantable Devices: Pad printing is employed on implantable medical devices such as pacemakers, artificial joints, and orthopedic implants to provide necessary instructions, identification numbers, or branding.

Medical Containers and Packaging: Pad printing is used to print information, logos, or labels on medical containers, such as vials, ampoules, and blister packs, ensuring clear identification and instructions for use.

Prosthetic Devices: Pad printing is used to mark prosthetic devices with important information, such as sizing, care instructions, or branding.

Hearing Aids: Pad printing is commonly used on hearing aids to mark controls, battery compartments, or to personalize the device.

Diagnostic Test Strips: Pad printing is employed to print color indicators, identification numbers, or branding on diagnostic test strips for accurate interpretation and tracking.

Labware and Laboratory Equipment: Pad printing is used to mark laboratory glassware, Petri dishes, test tubes, and other lab equipment with important information, including measurements, graduations, or branding.

Advantages of Pad Printing

Versatility: Pad printing can be applied to a wide range of medical devices, materials, and shapes. It is compatible with both flat and irregular surfaces, allowing for precise and consistent printing on complex geometries, curves, and textured surfaces.

High Resolution and Detail: Pad printing enables the printing of intricate designs, small text, barcodes, and fine details with high precision. This is particularly important for medical devices that require accurate markings, identification numbers, lot codes, or other important information.

Durability and Resistance: Pad printing inks used in the medical sector are formulated to withstand sterilization processes, cleaning agents, chemicals, and environmental factors. The prints exhibit excellent adhesion and durability, ensuring the longevity of the markings throughout the lifespan of the device.

Regulatory Compliance: Pad printing in the medical sector meets stringent regulatory requirements, such as FDA regulations and ISO standards. The inks used are often biocompatible and meet specific medical industry regulations, ensuring the safety and suitability of the printed devices.

Cost-effective: Pad printing offers cost advantages for high-volume production due to its efficient and automated printing process. It allows for rapid printing speeds, reducing production time and costs associated with printing medical devices.

Customization and Branding: Pad printing enables the printing of logos, branding, and custom designs on medical devices, helping to create a distinct identity for the manufacturer and enhance product recognition in the market.

Traceability and Identification: Pad printing allows for the printing of essential information, such as lot numbers, serial numbers, expiration dates, or instructions for use. This enables easy traceability, inventory management, and ensures accurate identification and tracking of medical devices.

Flexibility: Pad printing offers the flexibility to use a variety of inks, including specialized inks for specific applications such as biocompatible inks for direct contact with skin or body fluids. This flexibility ensures compatibility with different materials and substrates used in medical devices.

EPIC – THE Pad Printing Machine

In the medical industry, state-of-the-art pad printing machines are essential for printing on various medical instruments. EPIC pad printing equipment is specifically designed to meet the printing needs of the medical industry, offering top-notch performance and requiring minimal space.

EPIC pad printing machines are capable of printing on a wide range of medical devices, including catheters, tubes, syringes, handles, thermometers, drug dosing devices, face masks, medicine strips, centrifuge tubes, ampoules, counter wheels, and more. These machines are engineered to meet the high-quality and safety requirements of the medical industry, ensuring precise and reliable printing on medical devices.

Designed with industry-specific needs in mind, EPIC pad printing machines incorporate high-quality components that prioritize safety, reliability, and precision. These machines deliver consistent and accurate results, crucial for the medical industry where quality and safety are paramount.

EPIC understands the unique demands of the medical industry and strives to provide pad printing solutions that meet and exceed those requirements. The machines are meticulously designed and manufactured to ensure compliance with industry standards, enabling the printing of crucial information and markings on medical devices with confidence.

When it comes to medical device printing, EPIC pad printing machines offer a reliable and efficient solution. With their focus on safety, quality, and precision, these machines are ideal for fulfilling the printing needs of the medical industry while adhering to the stringent regulations and standards that govern the sector.

Why Choose EPIC Pad Printers for medical industry printing needs?

Over 35 Years of Experience: With more than 35 years of experience in building pad printing machines, Spinks brings a wealth of expertise and knowledge to the table.

Extensive Track Record: Having successfully delivered over 1000 printing projects to medical device manufacturers, Spinks has a proven track record of providing reliable and effective printing solutions.

Comprehensive Printing Solutions: At Spinks, you can find all your printing solutions in one place. Come with your project requirements, and leave with a tailored solution that meets your specific needs.

Compliance with Industry Regulations: Spinks understands the strict safety regulations governing the medical industry. When designing the machines, all relevant parameters are taken into consideration to ensure compliance and adherence to industry standards.

Seamless Integrations: Spinks makes it easy to integrate their pad printing machines with your existing printing or laser marking lines, allowing for smooth workflow integration and operational efficiency.

Trusted by Industry Giants: Spinks has delivered large-scale automations and Special Purpose Machines (SPMs) to renowned companies such as Cipla, Shaily, GSK, Morepen Pharma, Nanz Med, Adge Industries, and other prominent names in the medical industry.

Customization Expertise: With extensive experience in serving the medical industry, Spinks excels in creating customized solutions and automation tailored to specific requirements.

Strong Service and Support: Spinks stands behind its customers with a dedicated service and support team. Their enthusiastic and knowledgeable professionals are committed to providing prompt assistance and ensuring customer satisfaction.

Traceability Solutions: Spinks goes beyond machine manufacturing by offering traceability solutions to the medical industry. Utilizing state-of-the-art software and AI technologies, they provide innovative solutions to enhance traceability and quality control processes.

European Sourced Major Components: At Spinks, we prioritize the highest quality and cost-efficiency in our EPIC pad printers. That's why we carefully source all the major components from reputable European suppliers. By selecting components from Europe, we can guarantee exceptional quality and reliability in our pad printers while maintaining optimum costs. No Chinese components are used in EPIC machines. *

Inks , colors and paints For Medical Industry

Printing cannot happen without inks. In the medical industry, various types of inks are used for printing on medical devices and equipment. These inks are specifically formulated to meet the stringent requirements of the industry, ensuring safety, durability, and compliance with regulatory standards. Here are some main requirements from an ink used in medical products manufacturing.

- Biocompatible Inks

- Sterilization-resistant Inks.

- Chemical-resistant Inks

- UV-curable Inks

- Solvent-based Inks

- Water-based Inks.

- Direct Food Contact Inks

It's important to note that the selection of inks for medical industry printing depends on the specific application, substrate, and regulatory requirements. Manufacturers and printers in the medical sector must adhere to strict guidelines to ensure the safety, quality, and reliability of the printed medical devices.

Spinks world has printing ink solutions for the pharmaceutical and medical industry looking for industrial medical grade standards such as REACH, USP Class VI, ROHS, BPA free, chemical, mechanical and corrosion resistance, FDA and Sterilization compliant, ISO Certification, Adhesion and Durability.

*Check with our team for models.

Pad printing inks for printing on Medical Components & Equipement