In the automotive industry, achieving high-quality decoration on automotive parts is essential. Pad printing is a remarkable technique that allows for splendid decoration on these parts. Meeting the industry's strict standards and regulations for printing on automotive components is a necessity. That's why Spinks World offers EPIC machines, equipped with cutting-edge technology, to ensure compliance with these standards and safety regulations.

EPIC machines by Spinks World are top-notch, incorporating the latest components to tackle the challenging printing situations encountered in the automotive sector. They are specifically designed to meet the highest quality requirements. Our years of experience in the field have enabled us to develop EPIC machines that deliver exceptional outcomes in automotive printing .

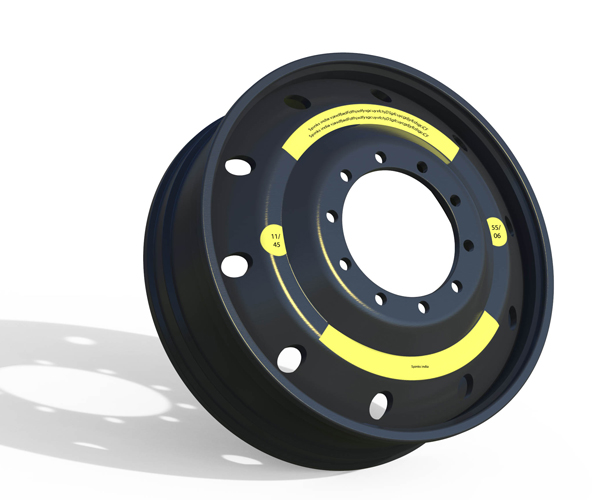

The automotive industry encounters several challenges when it comes to pad printing . Various types of plastics are used in automotive components due to their versatility, lightweight nature, and durability. Some common plastics used in automotive applications include PP, PU, ABS, PC, PET, PA/nylon, PE and others. Most of the automotive components Molded from these plastic materials include instrument panels, door trims, electrical connectors, interior and exterior trim components, engine covers, pipes and tubings, mirror housings, instrument cluster covers, grills, wheel covers, gear shifter knobs and many more.

Some of the key challenges faced while printing on automotive parts include:

Adhesion and durability are critical considerations when it comes to printing on automotive components. These parts are subjected to a range of environmental factors like temperature variations, UV radiation, moisture, and chemicals. It is essential to ensure that the printed image adheres strongly to the surface and maintains durability under these challenging conditions.

Spinks World offers comprehensive solutions for automotive component pad printing and laser marking, addressing these concerns effectively. Our expertise and advanced technologies enable us to deliver exceptional adhesion and durability for automotive applications. If you would like to learn more about our solutions and discuss your specific requirements in detail, please don't hesitate to contact us. We are here to assist you. Surface Variation: The automotive industry presents an array of automotive parts characterized by varying shapes, sizes, and materials, often featuring curved or irregular surfaces. Ensuring a uniform and accurate printing result on such diverse surfaces can be a formidable task. Pad printing stands out as the ideal solution in this scenario, as it is the sole technique capable of meeting this challenge by enabling printing by silicone pad on 3D parts. To cater to the diverse range of automotive components with varying shapes and sizes, our pad printing equipment is versatile. It can effectively print on substrates such as PC/ABS/PMMA, PU, coated plastics, aluminum, chrome-plated plastics, powder-coated metals, and more. With the EPIC Pad Printing Machine, you have the flexibility to choose the appropriate cliché plate, hard or soft pad, thick or thin ink, adjust the quantity of thinner, and even modify the machine's pressure based on the substrate, product, and size.

Compliance with Regulations: Ensuring Regulatory Compliance: The automotive industry operates under stringent regulations and standards, particularly when it comes to safety, quality, and environmental impact. Pad printing, as a printing technique used in this sector, must adhere to these regulations, which encompass factors such as chemical composition, emission levels, and material restrictions. At Spinks World, we place a strong emphasis on environmental compliance. Our commitment is reflected in the inks we offer, which are not only eco-friendly but also resistant to chemicals, and compliant with various regulations, including ROHS, GADSL, REACH, Directive 2006/122/EC (PFOS), Directive 2005/84/EC (Phthalates), OEM specifications, ISO standards, ASTM (D1475): Density of liquid coatings, inks, and related products, ASTM (D2369): VOCs, as well as industry standards.

Our automotive component printing solutions are tailored to address the specific requirements of this industry sector, ensuring compliance with relevant regulations and standards. For more information on how we can assist you in meeting your regulatory obligations, please don't hesitate to contact us.

Production Efficiency: To meet the demands of high production volumes without sacrificing quality, it is crucial to optimize the speed, accuracy, and repeatability of pad printing operations.

Introducing EPIC pad printers, the ideal solution for those facing production efficiency challenges in pad printing automotive components. These advanced machines are specifically designed to streamline the printing process, ensuring swift and precise printing while maintaining exceptional quality standards.

If you're seeking to overcome production efficiency issues in pad printing automotive components, we invite you to reach out to us for a detailed discussion to optimize your production processes and drive efficiency together. Accurate Color Matching and Branding: Meeting the color requirements and branding guidelines set by automotive manufacturers is essential.

At Spinks World, we understand the stringent demands of our automotive component customers who expect exact color matching. Our dedicated team of color matching professionals excels in fulfilling these requirements.

With the aid of advanced equipment and tools such as spectrophotometers, colorimeters, light booths, color management software, Pantone color guides, ink mixing systems, and color evaluation tools, we ensure exceptional color accuracy and consistency. These resources empower us to deliver outstanding results and meet the high expectations of our valued customers in the automotive industry.

When it comes to color matching and branding for automotive components, Spinks World has a proven track record of success. Our commitment to precision and customer satisfaction sets us apart, ensuring that your automotive components meet the exacting standards and unique branding needs of your organization.

Traceability and SerializationIn the automotive industry, the need for unique identification, traceability, and serialization of components is crucial for ensuring quality control and managing warranties. Spinks offers an exceptional solution for achieving automotive traceability on automotive parts by harnessing the power of Markolasers.

Substrate CompatibilityIn the realm of automotive components, a wide array of materials such as plastics, metals, glass, and coated surfaces are utilized. To achieve optimal adhesion and print quality, it is essential to ensure compatibility between the ink formulation and the specific substrate. At Spinks World, our proficient experts excel at addressing the challenges associated with pad printing and substrate compatibility. With over 25 years of experience in the field, we possess the expertise to seamlessly handle such issues.

Addressing these challenges requires specialized expertise, advanced equipment, and customized solutions tailored to the unique requirements of the automotive industry. By partnering with experienced pad printing providers and leveraging innovative technologies, automotive manufacturers can overcome these challenges and achieve high-quality, durable, and compliant printing on their components.

We offer current technology EPIC pad printers for qualifying the standards and safety regulations needed for foremost printing in the automotive industry. EPIC printers by Spinks World are top-notch machines made with the latest components to deal with the challenging situations that can come during printing in the automotive sector. When it comes to pad printing in the automotive industry, Spinks World's EPIC machines and comprehensive range of solutions are the ideal choice to meet industry standards and achieve exceptional product quality.

Our pad printing equipment for automotive is ideal to meet the standards which are mandated for the automotive sector.

Pad printing inks for printing on Automotive Components