The printing industry has been an important aspect in packaging, especially in sectors like cosmetics and Fast-Moving Consumer Goods (FMCG), where the quality and design of packaging play a critical role. The EPIC Pad Printing Machine has emerged as an advanced solution, bridging the gap between design complexity and production efficiency. It's a go-to choice for manufacturers looking to produce high-quality prints on diverse packaging materials.

Pad printing, unlike screen or digital printing, uses a silicone pad to transfer ink onto a product's surface, making it highly effective for irregularly shaped objects. The EPIC Pad Printing Machine excels by offering cutting-edge technology, including automation, customization, and high precision, essential for industries like cosmetics and FMCG, where branding and aesthetics are critical.

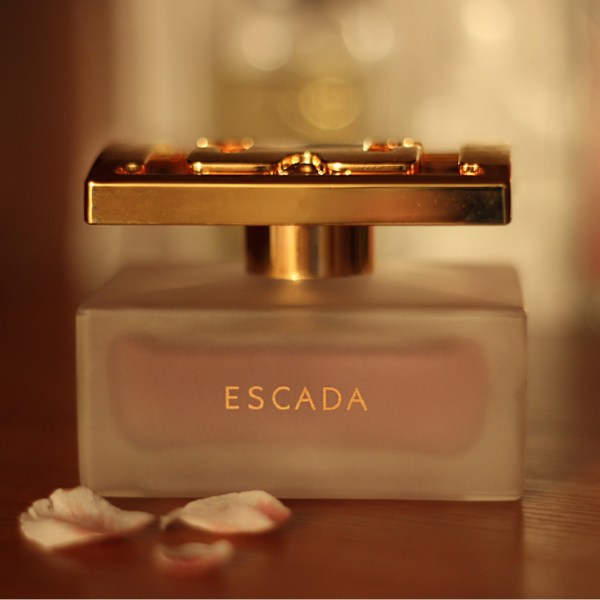

Pad printing is widely used in the cosmetic / FMCG industry for efficiently printing on a variety of products and packaging materials. Here's how it is applied:

Branding and Logos: Pad printing is used to imprint company logos, brand names, and other essential product information on FMCG items such as bottles, cans, and containers.

Product Information: Batch numbers, expiry dates, and barcodes are often pad printed on packaging, ensuring the information is legible and durable.

Decoration: Pad printing helps in adding decorative elements to FMCG products, enhancing their visual appeal and marketability.

In essence, pad printing in the FMCG industry helps in mass customization, consistent branding, and efficient production.

Benefits for Cosmetics Industry

![]() Precision for Fine Details: Cosmetics often require delicate, small-scale branding, which the EPIC Pad Printing Machine excels at.

Precision for Fine Details: Cosmetics often require delicate, small-scale branding, which the EPIC Pad Printing Machine excels at.

![]() Multi-Surface Compatibility: Whether it’s glass, plastic, or metal packaging, the machine adapts to different materials without sacrificing print quality.

Multi-Surface Compatibility: Whether it’s glass, plastic, or metal packaging, the machine adapts to different materials without sacrificing print quality.

![]() Vibrant and Long-Lasting Prints: The advanced ink technology ensures that printed designs remain sharp and vibrant even after exposure to varying environmental conditions.

Vibrant and Long-Lasting Prints: The advanced ink technology ensures that printed designs remain sharp and vibrant even after exposure to varying environmental conditions.

Benefits for FMCG Industry

![]() Speed and Efficiency: Capable of producing thousands of prints per hour, this machine is built for high-demand environments.

Speed and Efficiency: Capable of producing thousands of prints per hour, this machine is built for high-demand environments.

![]() Cost-Effective Operations: Its automation reduces manual intervention, cutting down labor costs and improving overall production efficiency.

Cost-Effective Operations: Its automation reduces manual intervention, cutting down labor costs and improving overall production efficiency.

![]() Versatility in Packaging Materials: Whether it’s flexible packaging, rigid containers, or cartons, the machine offers adaptability to print on a wide range of materials.

Versatility in Packaging Materials: Whether it’s flexible packaging, rigid containers, or cartons, the machine offers adaptability to print on a wide range of materials.

Suitable Packaging Types

One of the key reasons the EPIC Pad Printing Machine is highly sought after is its ability to print on a vast array of packaging types. Some of the most common materials include:

Glass

Plastic

Aluminum

EPIC Pad Printing Machine Features

The EPIC Pad Printing Machine brings innovation and convenience to the forefront with its superior range of features. Designed for high precision and adaptability, it stands out due to its advanced controls and ease of use.

![]() Automated Precision: The machine integrates intelligent controls for automatic adjustments, ensuring uniform print quality across multiple products

Automated Precision: The machine integrates intelligent controls for automatic adjustments, ensuring uniform print quality across multiple products

![]() Customization Capabilities: From small to large production runs, the machine allows for quick setup changes to accommodate various design needs.

Customization Capabilities: From small to large production runs, the machine allows for quick setup changes to accommodate various design needs.

![]() User-Friendly Interface: Its intuitive interface makes it accessible for operators, minimizing downtime and learning curves.

User-Friendly Interface: Its intuitive interface makes it accessible for operators, minimizing downtime and learning curves.

![]() High-Speed Production: The machine is capable of handling large volumes, making it ideal for the FMCG sector, where fast turnarounds are critical.

High-Speed Production: The machine is capable of handling large volumes, making it ideal for the FMCG sector, where fast turnarounds are critical.

PAD PRINTING MACHINE FOR COSMETICS/FMCG and other packaging

FAQs

Ques 1 : What materials can the EPIC Pad Printing Machine print on?

Answer: The machine is compatible with a wide range of materials including plastic, glass, aluminum, and many more.

Ques 2 : How fast can the EPIC Pad Printing Machine operate?

Answer: It can produce thousands of prints per hour, making it ideal for high-volume industries like FMCG.

Ques 3 : Is the EPIC Pad Printing Machine environmentally friendly?

Answer: Yes, it supports eco-friendly inks and is designed to minimize waste and energy consumption.

Ques 4 : Can the EPIC Pad Printing Machine handle custom designs?

Answer: Absolutely, it’s designed to quickly adapt to custom printing needs with minimal setup time.

Ques 5 : How does pad printing compare to digital printing?

Answer: While digital printing offers flexibility, pad printing is more cost-efficient for high-volume production and complex surfaces.

Ques 6 : What is the lifespan of the EPIC Pad Printing Machine?

Answer: With regular maintenance, the machine is built to last for many years, offering excellent long-term value.