Contact us today to discover how our fully-automatic toggle printing solution can transform your manufacturing processes. Embrace the future of efficient and precise toggle printing and gain a competitive edge in your industry. Experience the difference that our cutting-edge solution can make in your business success.

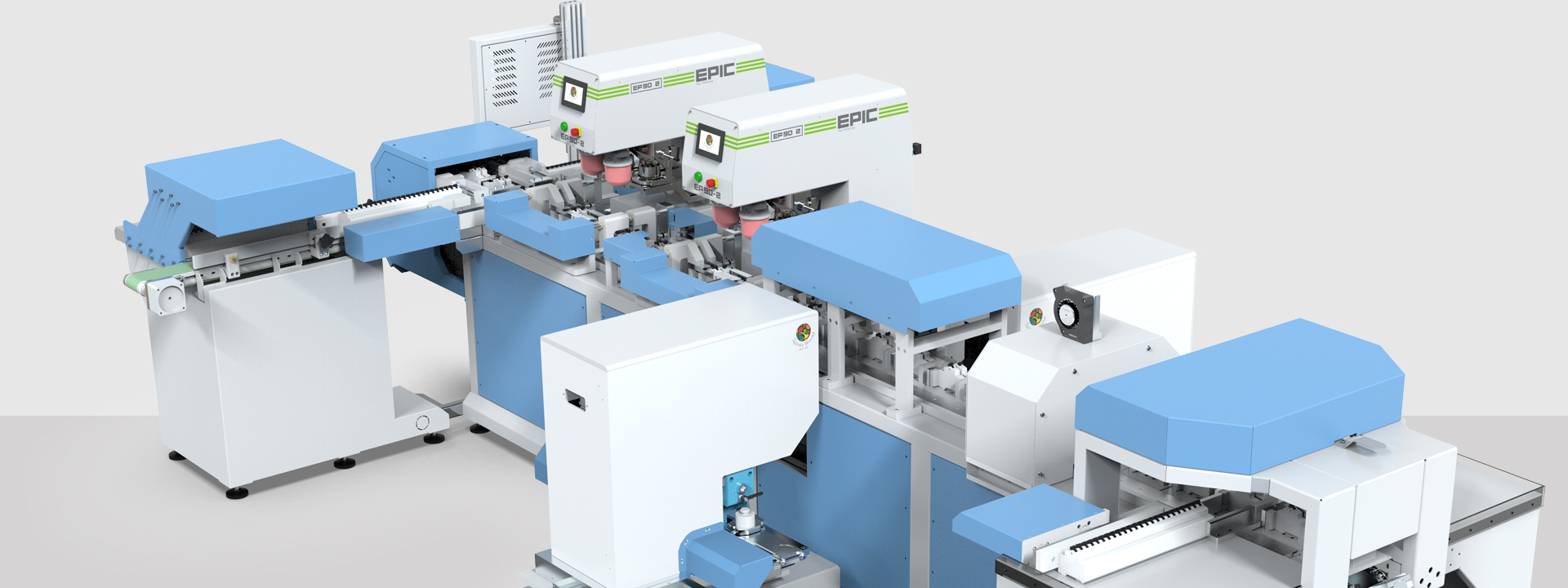

Pad Printing Automations

Achieve Seamless Efficiency with Our Fully-Automatic Toggle Printing Solution

When it comes to toggle printing, efficiency and accuracy are paramount. Our engineering design team has developed a state-of-the-art fully-automatic solution that caters to these needs. This innovative system is designed to accommodate three variants, revolutionizing the toggle printing process. Let's explore the remarkable features of our solution and how it can streamline your operations.

SPM pad printing Sample