Magnetic vs. Non-Magnetic Options

In the intricate world of pad printing, every component plays a critical role in ensuring precision and consistency. One such vital component is the ink/doctoring cup, often referred to as the doctoring cup. Before diving into the differences between magnetic and non-magnetic ink cups, let's first understand what ink cups are and why they are crucial.

What Are Ink/Doctoring Cups?

Ink cups, or doctoring cups, are essential components in pad printing machines. Their primary function is to hold and distribute ink onto the printing plate (cliché). The ink/doctoring cup contains ink and a doctoring ring that scrapes excess ink from the plate, ensuring that only the required amount is transferred to the printing pad. This "doctoring" process is fundamental for achieving a precise, consistent, and clean print, which is the cornerstone of successful pad printing.

In simpler terms, the ink cup slides across the plate, applying ink to the etched area and leaving only a small amount behind. This method ensures that the final print is sharp and accurate, without any smudging or over-inking.

Types of Ink Cups

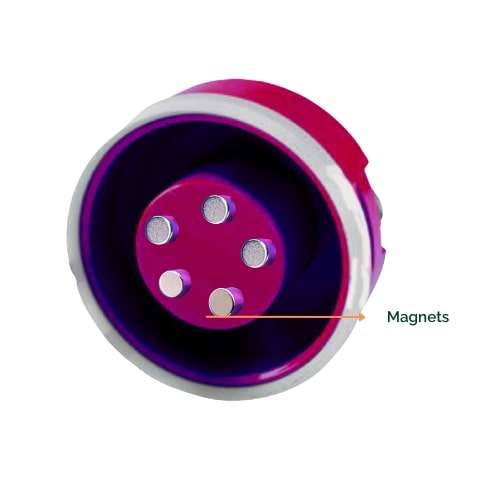

1. Magnetic Ink Cups:

How They Work: Magnetic ink cups act as self-doctoring units. Powerful magnets create the necessary downforce to clean the plate, requiring the pad printing machine to simply pull the cup back and forth across the plate.

Advantages:

- Provide stability and precision.

- Good for multi-color applications.

Disadvantages:

- Heavier and bulkier due to the magnets.

- Magnets can limit ink mixing within the cup and may affect ferrous-based pigments in inks.

- High pressure on cliché plates leads to faster wear and tear of clichés.

- Less space for mixing ink inside the cup.

- Scooping of ink from the center of patch of artwork.

2. Non-Magnetic Ink Cups:

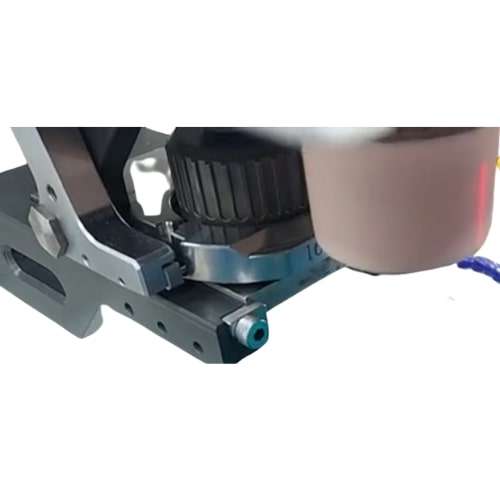

How They Work: Non-magnetic ink cups rely on mechanical clamping, where pressure is applied by the pad printing machine to an outer flange or centering hole in the cup. This system is compact and effective, even in high-speed applications.

Disadvantages:

- More cost-effective and versatile.

- Can be used with a wide variety of cliché plates, including pure aluminum and ceramic, not just steel.

- Lighter in weight, easier to handle, and cause less wear on cliché plates, extending their life.

- Allows for better ink mixing within the cup.

- Enables sharper artwork and finer details in printing.

- Easier to dose thinner from top while the machine is still running.

Disadvantages: May require more complex systems for multi-color applications compared to magnetic cups.

EPIC and Tampoprint AG: Leaders in Non-Magnetic Ink Cups

EPIC and Tampoprint AG are two companies that exclusively use non-magnetic ink cups in their pad printing machines, and they have solid reasons for doing so:

Cliché Compatibility

Non-magnetic ink cups can be used with a variety of cliché plates, including aluminium and ceramic, which are not compatible with magnetic ink cups.

Improved Ink Mixing

Without the space-consuming magnets, non-magnetic cups offer better ink mixing within the cup, ensuring consistent quality.

Extended Cliché Life

Reduced pressure on the plates means longer cliché life, making non-magnetic ink cups a cost-effective solution in the long run.

Ink Variety

Unlike magnetic cups, non-magnetic cups do not interfere with ferrous-based pigments, allowing for a broader range of inks.

Lightweight and Efficient

EPIC Non-Magnetic ink cups are made of aeronautical grade alloy, which are light in weight and tough. The ribbed ink cup technology of EPIC pad printers (Patent Pending No. 202311029799), allows dissipation of heat, which may interfere with quality and viscosity of ink in use.

Sharper Prints

EPIC’s non-magnetic ink cups have been tested for printing fine lines (as thin as 35mm), demonstrating their superiority in delivering sharp and precise artwork.

Conclusion

When selecting an ink cup for pad printing, it's essential to consider your specific needs—whether it's precision, cost-effectiveness, or versatility. Magnetic ink cups may offer stability in multi-color applications, but they come with limitations that non-magnetic ink cups effectively address. Companies like EPIC pad printing and Tampoprint AG demonstrate that non-magnetic options can provide better performance, longevity, and flexibility, making them a preferred choice for many pad printing operations.

In the long run, non-magnetic ink cups offer an innovative and cost-effective solution, ensuring that your pad printing process remains efficient and high-quality. Whether you're printing on medical devices, automotive parts, or promotional products, choosing the right ink cup can make all the difference.